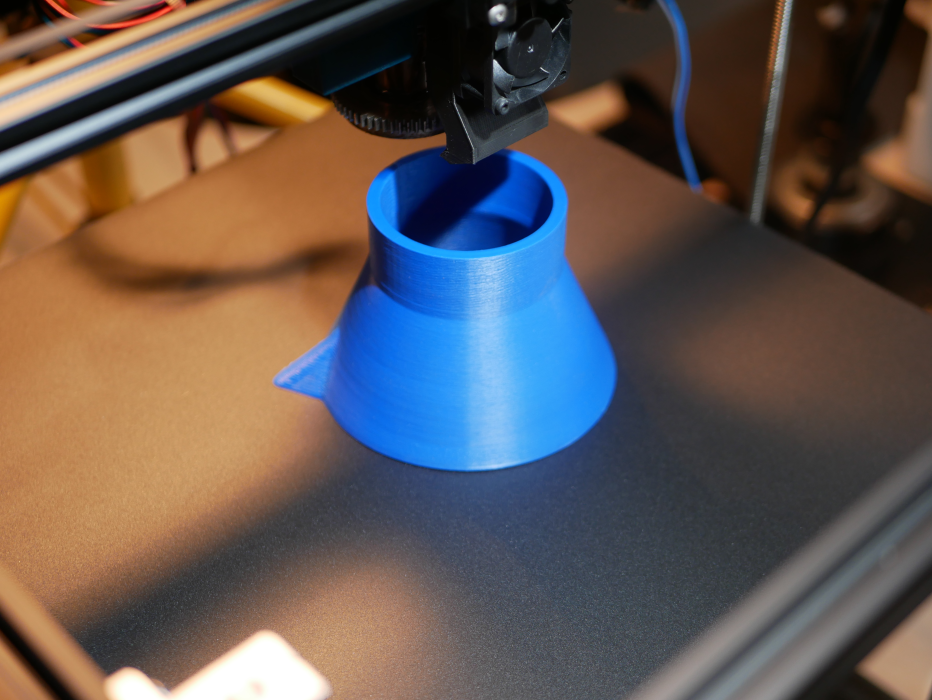

Since its inception more than 2 decades ago, FDM printing has been stuck in using circular shaped fixed-size nozzles.

Small nozzles are slow for printing large objects, larger nozzles result in loss of detail and geometric accuracy.Finally, with our continuous variable nozzle technology, there now is a solution for creating strong, full-sized and detailed objects in a matter of minutes.

Learn more ...Improved quality with high flowrate

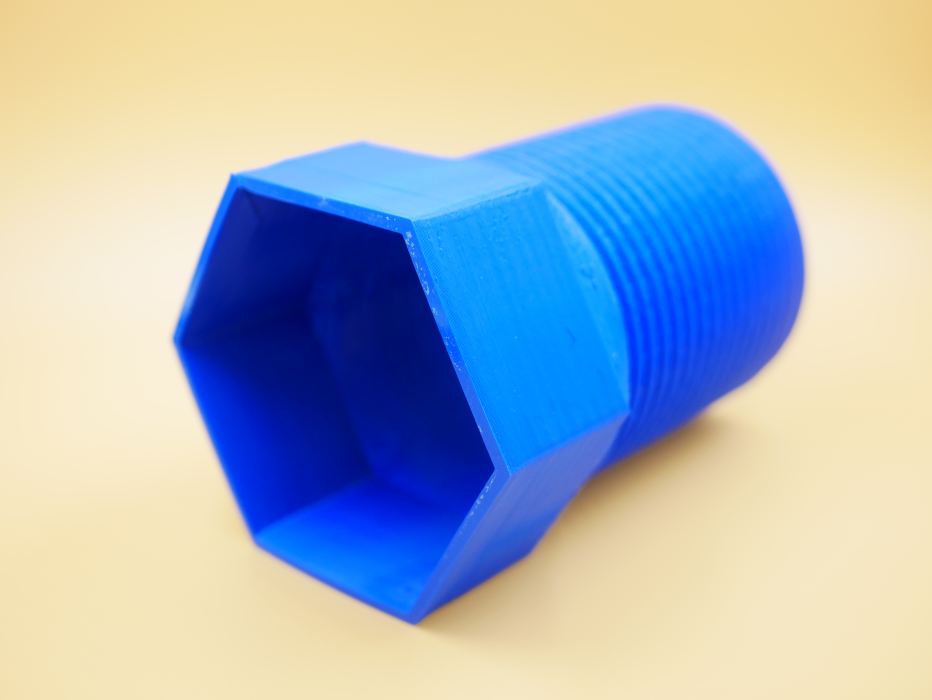

The Sculpman nozzle has a rotating rectangular opening, and lays down 'ribbons' of build material, instead of circular 'spaghettis'. This means that layer edges are less rounded, no matter how wide they are deposited. Visual quality is therefore improved while wider, stronger walls are extruded in a single stroke.

Learn moreStrong parts

Better object strength results from wider extruded ribbons of material. Outside walls and hole perimeters are drawn in a multi-mm wide single stroke, providing superior strength. Solid infill is fast to print and sparse infill creates thicker internal struts. The result is an improved layer coherency and an important increase in part strength, without any adverse effect on the build speed or geometric or visual quality.

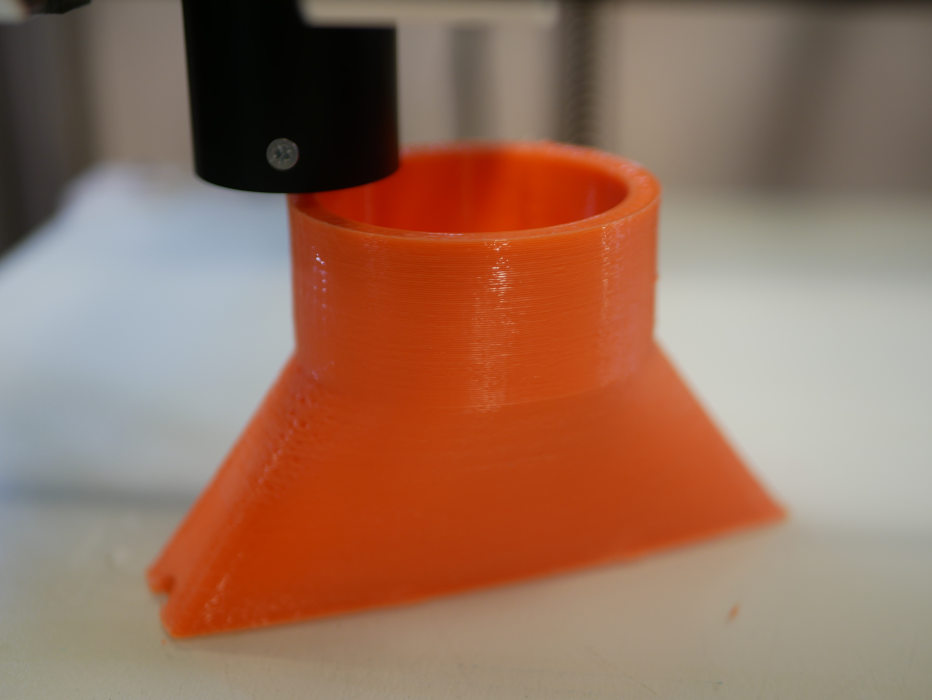

Learn moreUp to 20 times faster

Extruding with a width of up to 10mm (or more), even large objects can be printed in minutes. Because our nozzle is continuously variable down to 0, there is no loss of feature detail where it is needed.

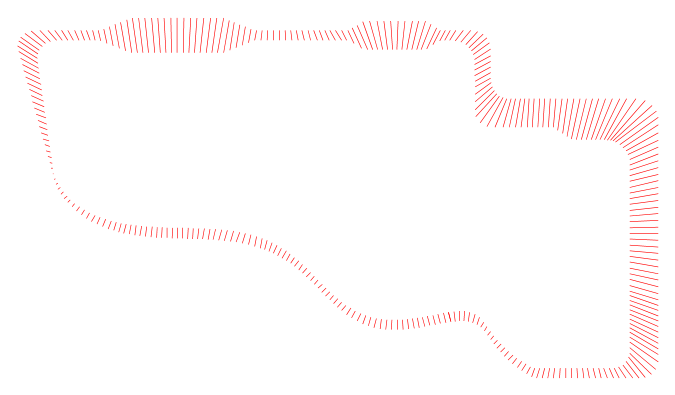

Learn moreIntelligent planning software

A continously variable output opening demands an intelligent motion planning algorithm. Our unique, in-house developed planning system is fully cloud-based and designed to be easily integrated in existing slicing frontends.

Learn more